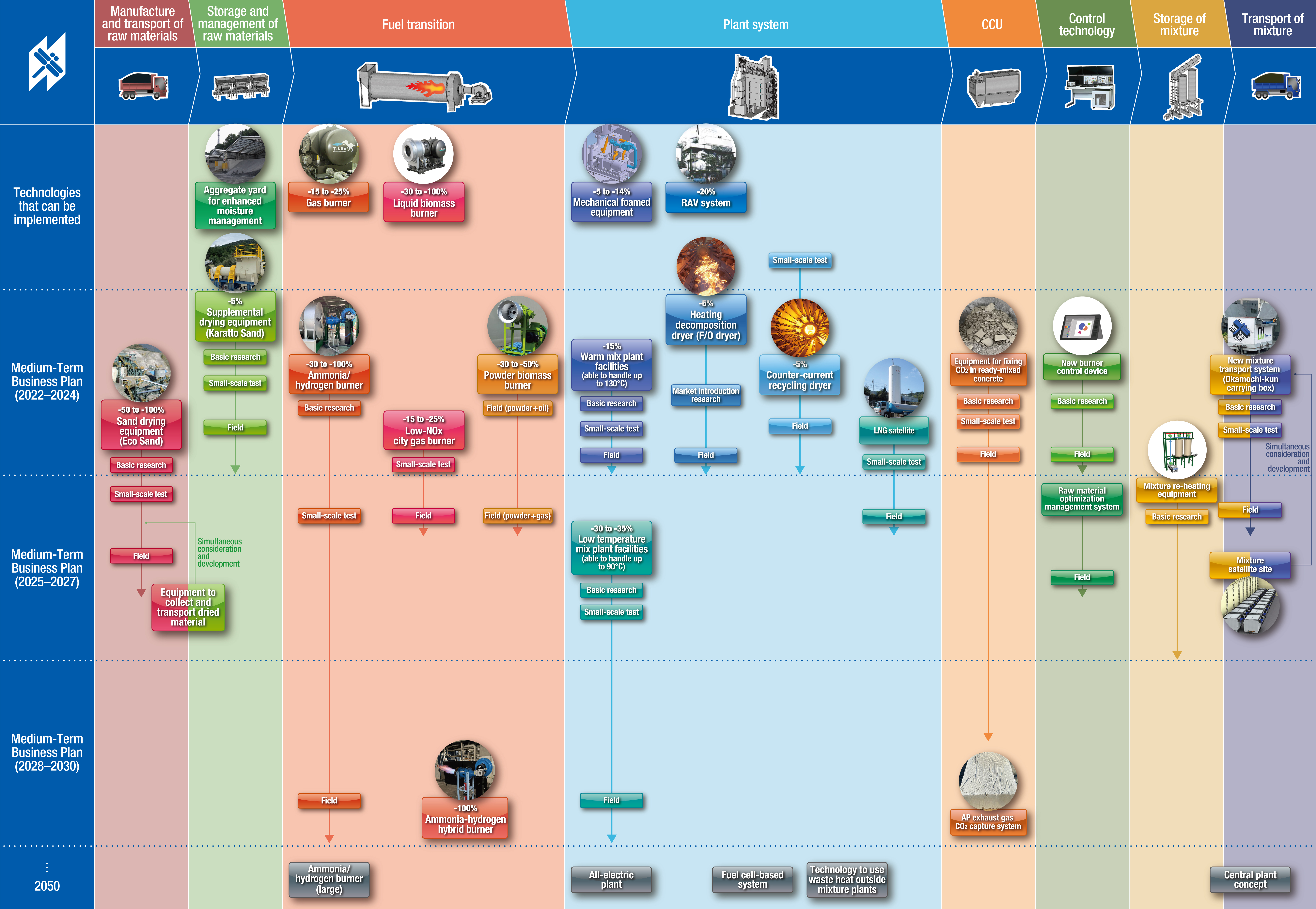

- Top

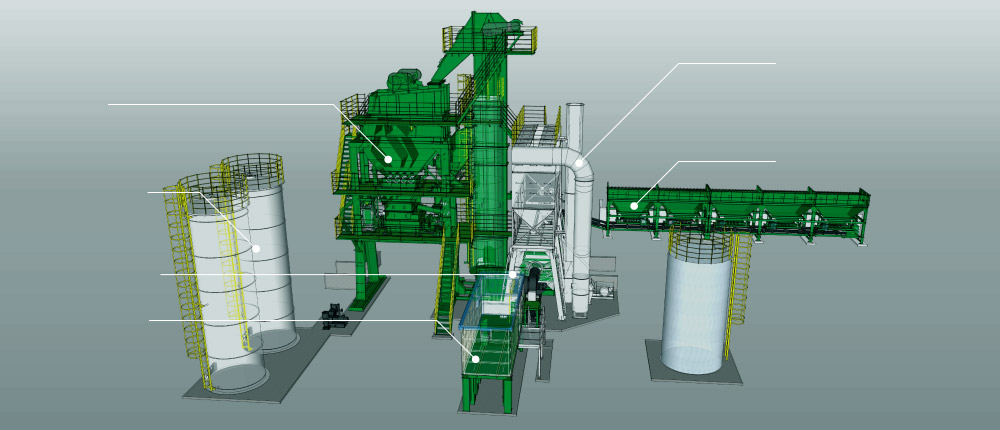

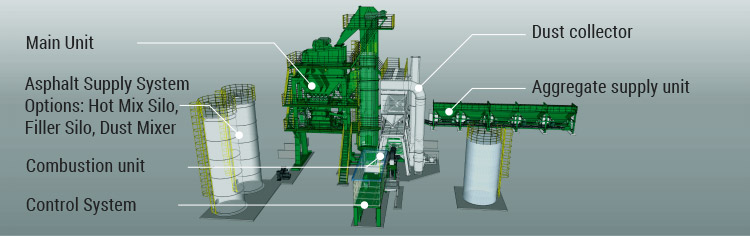

- Asphalt Mixing Plant

- Overview

Overview

Design Concept

CLEAN & SILENT

COST-SAVING

COMPACT

DESIGN

EASY

MAINTENANCE

STABLE

PRODUCTIVITY

HIGH

DURABILITY

ENVIRONMENT

FRIENDLY

Details of Design

Main UnitMore Info

The key to high quality hot mix and continuous operation

Vibrating screen – high accuracy screening

Hot Bin – extends productivity of asphalt plant

Mixer – speedy and thorough mixing

Screen

- Powerful vibration generator

- Wide amplitude

- High vibrating frequency

- Large screening area

⇒High screening efficiency and accuracy

Hot Bin

- Number and volume of hot bins can be increased upon request of customer (optional).

- Continuous heating and mixing time can be extended by increasing the hot bin's storage capacity

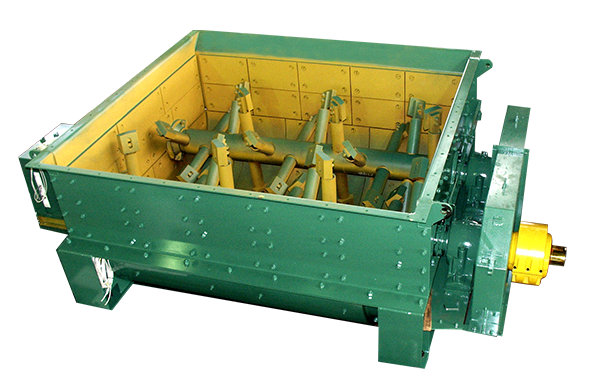

Mixer

- Powerful and dynamic flow by twin-shaft pugmill mixer

- Optimal mixing life zone

- Speedy mixing

- High quality homogenous hot mix by circulation flow and double spiral flow

Aggregate supply unitMore Info

Feeder – Supply the optimal amount of aggregates to dryer

For the production of high-quality asphalt mixture, uniform and exact feeding of cold aggregates to the dryer is important.

In order to maintain a smooth feeding operation, the aggregates must be strictly segregated into particle sizes and stored in hoppers accordingly. Especially fine aggregates must be stored under cover so as to maintain a minimum and constant water content level.

Registering the supply capacity into the operation panel by appropriate calibration ensures that just the right amount of aggregate is automatically fed in according to the combination of each mix.

Combustion unitMore Info

Gas burner/Oil burner/Gas & Oil dual burner to choose from

High efficiency heat pack dryer – easy maintenance and improved performance

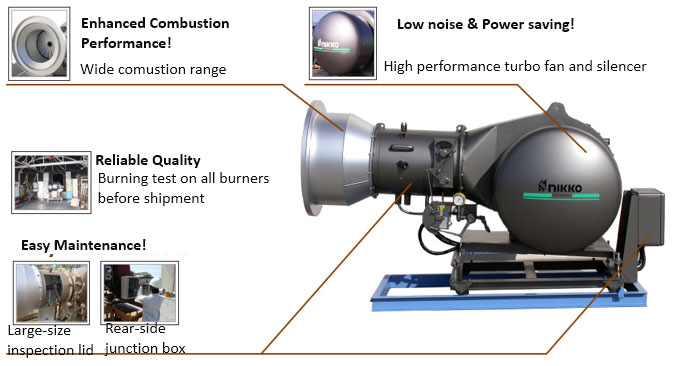

NTB Burner (Oil Burner)

For Higher Combustion Performance

NTB burner is a compact design, power-saving, and low-noise burner which reduces fuel consumption by its enhanced combustion performance.

It achieves an air ratio of 1:1 at maximum combustion with a wide combustible range (Max.1:5) and its optimal air-fuel mixture formation enables stable combustion.

NTBG Burner (Gas Burner)

High Combustion Performance & Environment-friendly

T-LEX Burner achieves an air ratio of 1.2 at maximum combustion with a wider combustible range compared to the conventional type and its optimal air-fuel mixture formation realizes stable combustion.

Low emission of nox (less than 18ppm)

40% reduction compared to conventional products

Low noise level

Newly designed high performance silencer reduces noise level by 5-10 d(A)

Conventional Type

- Zero emissions of SOx

- Reduced CO2 emissions

New Type

- Low NOx

- Low Air Ratio

- Enlarged combustion range

NTGO Burner (Gas & Oil Burner)

Hybrid Gas & Oil Burner

《Low environmental load + Instantaneously accommodates changes in the market》

Characteristics of Oil burner

- Low air-ratio combustion

- Large combustion

- Low noise level

- Space saving

- Simple control & Safe operation

Characteristics of Gas burner

- Low NOx& CO2 emissions

- Low noise

- Zero SOx emissions

- Low environmental load

Gas & Oil Burner

- Flexible response to changing fuel price and plant conditions

- Easy switching between gas and oil

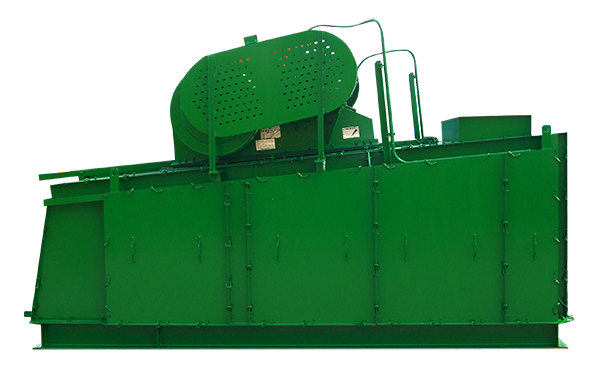

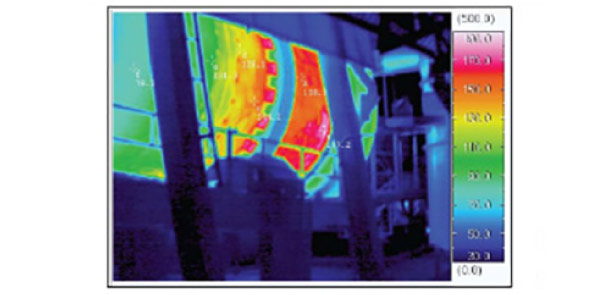

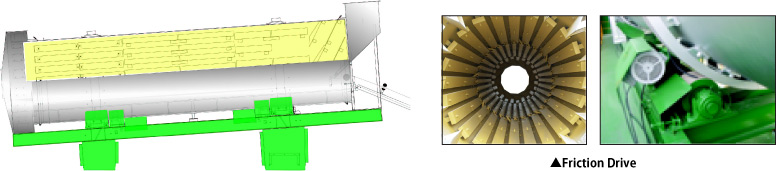

Heat Pack Dryer

- High Heat Efficiency

- Cost saving

- Low fuel consumption

- Low-noise,

- Easy maintenance

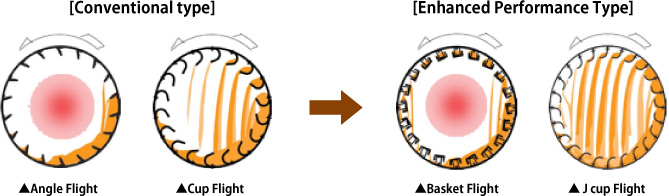

Compared to the conventional type, more segmentalized and uniform vailing improves heat transfer efficiency. The durability of the dryer is greatly improved by the reduction of radiating heat. The gear-less friction drive allows low noise operation and simple maintenance.

Structure

Flight

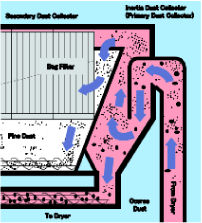

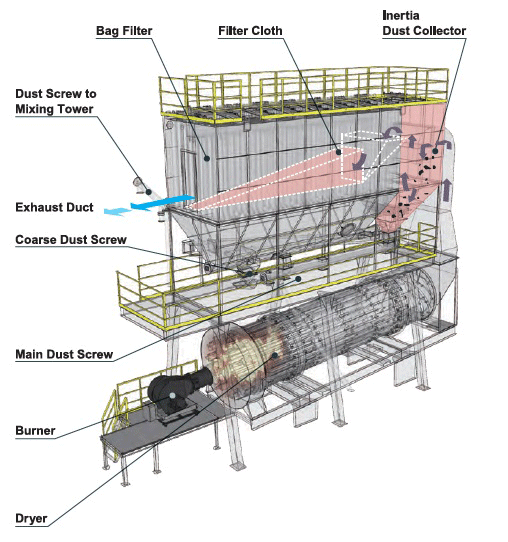

Dust collectorMore Info

Bag filter type or wet spray type & cyclone dust collector to choose from

Dry Dust Collector - BOND Type

- BOND (bag filter on dryer) structure

- Space saving

- Heat radiation from dryer retains optimal temperature at the bag house to prevent water condensation in the dust hopper unit

- Bag house shelters dryer from rain water and lengthens service life of dryer

- Detached dry cyclone (primary dust collector) and bag house (secondary dust collector) is combined

- Reduced heat radiation by a shortened smoke-way, exhaust gas enters the bag house at optimum temperature

- Hybrid structure reduces radiation area by 30%

- Speed of dust passing through filter cloth is reduced by 25% due to improved combustion efficiency

Wet Dust Collector

- An alternative, lower cost dust collector system

- Water is sprayed onto the exhaust gas and then evaporated

- Water vapor containing dust particles condenses and eventually flows out to the water tank

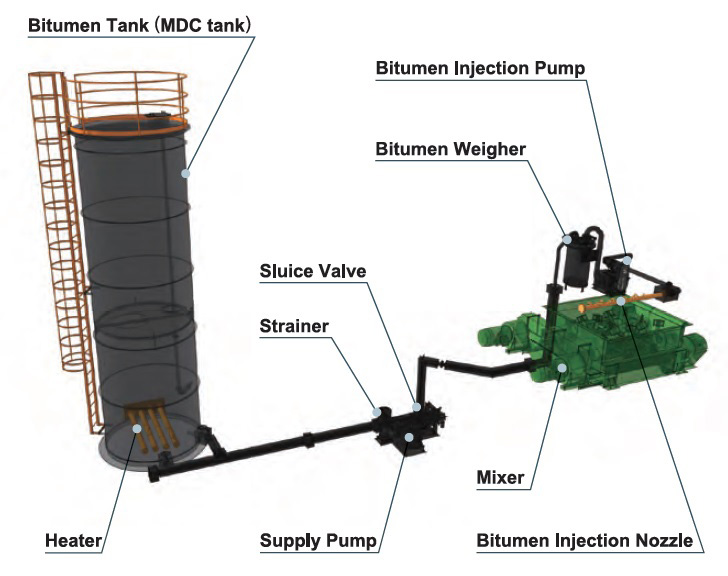

Asphalt Supply SystemMore Info

Electrical heating MDC tank or Hot-oil heating tank – adaptable to plant site condition

- Supplies asphalt from storage tank to mixer

- Accurate weighing and feeding to produce high quality hot mix

- Steady supply of homogeneous asphalt at uniform temperature

- (Optional) asphalt kettle for regions where only drummed asphalt is available

Electrical Heating

- Environmentally friendly

- Reduced heat dissipation

- Low installation cost

- Easy maintenance

- High safety standard

Hot-Oil Heating

- Fully automatic burner heats up oil to present temperature (around 180℃-210℃)

- Hot-oil circulating pump keeps heated oil circulating to maintain the asphalt tank, asphalt scale, spray device and pipe lines at preset temperature

- Hot oil heater control panel consists of temperature switch, pressure switch, oil tank level switch, 2-point temperature controller, and an alarm device

Options: Hot Mix Silo, Filler Silo, Dust MixerMore Info

Customizable Plant – to serve every need of the plant user

Filler silo

- To store bulk amount of filler

- Filler elevator is also available

Hot Mix Silo

- Equipped with anti-deterioration and temperature control device

- Planned production is possible (for example, construction work at night)

- Plant operation can continue until hot mix storage silo is filled up

- Several different types of asphalt hot mix can be stored at the same time

- Flexible choice of asphalt plant installation site (e.g.as an anti-pollution measure)

- Easy maintenance

- Compatible with Recycled Asphalt Pavement (RAP)

Dust Mixer

- High-performance spray device to mix dust particles with water

- Special designed blades prevent dusts from escaping

- Open top cover design for easy maintenance

Control systemMore Info

User-friendly system by highly reliable industrial computer

Japanese, English, Chinese and Russian language available

- Next-Duo - a centralized control system particularly developed for Nikko's asphalt mixing plant

- User-friendly and quick operation

- Windows® based system

- Highly reliable industrial computer and PLC modules

- Colour LCD and sophisticated graphic menu

- Available in various languages (Japanese, English, Chinese, Russian)

※Contact us for other languages